Understanding the Basics of Bridge Cranes

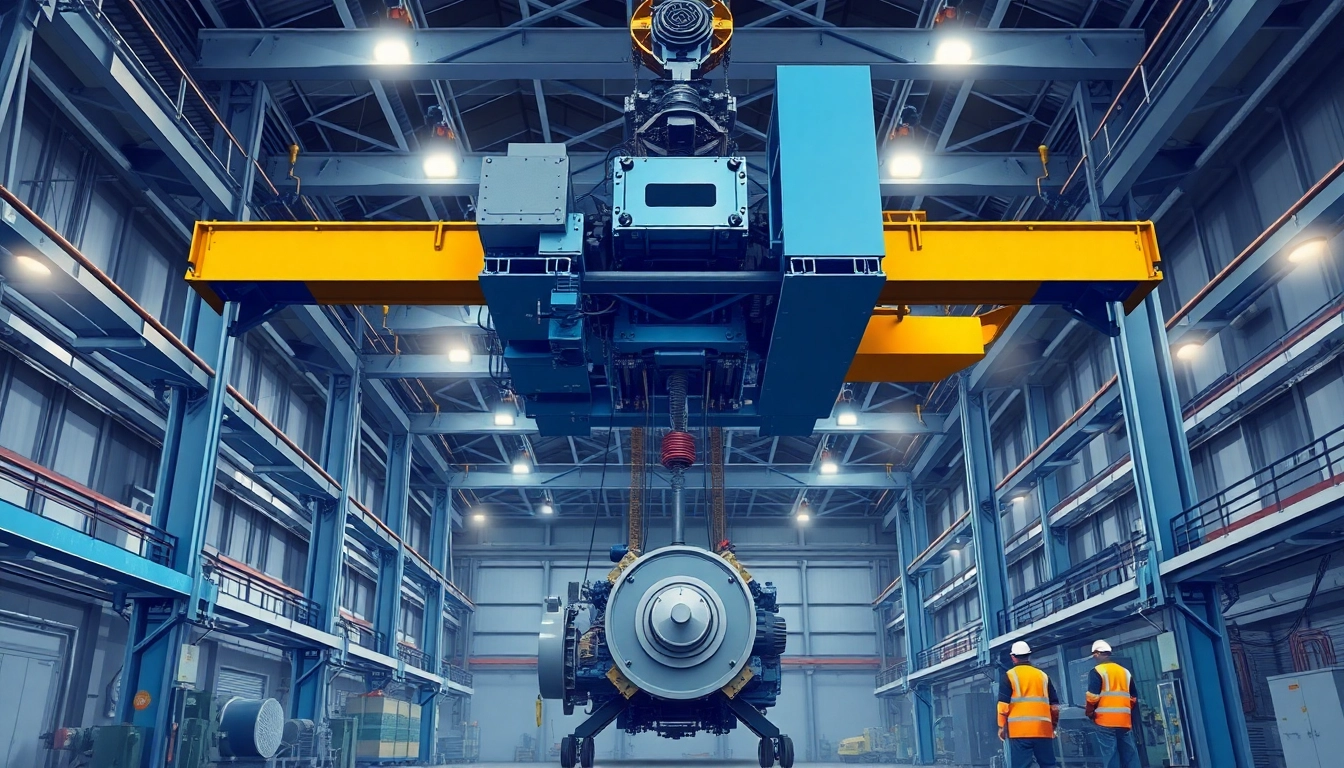

Bridge cranes, also known as overhead cranes, play a vital role in various industrial applications, providing an efficient solution for lifting and moving heavy loads across expansive workspaces. These cranes are designed to enhance operational efficiency and safety in environments where heavy materials must be transported over short to moderate distances. When exploring options, a bridge crane offers comprehensive insights into the technology and functionality that can meet specific lifting needs.

What is a Bridge Crane?

A bridge crane is a type of overhead crane that consists of a bridge beam that spans the width of a workspace, supported on both ends by a runway system that allows the crane to move horizontally. This design enables equipment to lift, move, and position heavy loads safely and efficiently within a defined area. Bridge cranes are especially prevalent in manufacturing, construction, warehouses, and shipping facilities, where they facilitate the handling of heavy materials such as metal sheets, beams, and machinery.

Key Components of a Bridge Crane

Understanding the key components of a bridge crane is essential for effective operation and maintenance. The primary elements include:

- Bridge Beam: The horizontal component that carries the load and moves along the runways.

- Runways: The tracks or rails on which the crane travels, typically mounted on columns.

- Hoist: The mechanism responsible for lifting and lowering the load, which can be electric or manual.

- End Trucks: The assemblies that connect the bridge beam to the crane wheels and facilitate movement along the runways.

- Control Systems: These regulate the crane’s movements, with options for manual or automated controls.

Types of Bridge Cranes and Their Applications

There are several types of bridge cranes, each designed for specific applications:

- Single Girder Bridge Cranes: Ideal for lighter loads, they feature a single bridge beam. Commonly used in manufacturing and warehousing.

- Double Girder Bridge Cranes: Suitable for heavier loads, these cranes have two bridge beams, providing extra strength and stability. They are often utilized in heavy-duty industrial applications.

- Freestanding Bridge Cranes: These are not attached to buildings and can be moved around workspaces. They are versatile and can adapt to various lifting requirements.

- Workstation Bridge Cranes: Designed to service specific workstations, these cranes enhance efficiency in smaller areas and provide flexible lifting options.

Benefits of Using Bridge Cranes in Industrial Settings

Enhanced Efficiency and Productivity

Bridge cranes significantly improve efficiency in industrial settings by allowing for faster and safer transport of heavy materials. With their ability to cover large areas, these cranes reduce the time workers spend moving items manually, thus streamlining operations. The integration of advanced technology, such as automated control systems and precision hoisting, further enhances productivity by minimizing human error and maximizing load handling capabilities.

Safety Features and Compliance Standards

Safety is paramount in industrial environments, and bridge cranes are equipped with numerous safety features to protect both operators and loads. Common safety features include:

- Load Limit Switches: Prevent overloading, ensuring that the crane operates within its designated capacity.

- Emergency Stop Systems: Allow for immediate cessation of crane operation in case of emergency or hazardous situations.

- Regular Inspections and Maintenance Protocols: Compliance with OSHA and other industry standards allows for safe operations and longevity of the crane.

Cost-Effectiveness Over Time

While the initial investment for a bridge crane can be substantial, the long-term benefits often outweigh the costs. These cranes reduce labor costs by automating lifting tasks and minimizing workplace injuries, leading to lower insurance premiums. Additionally, their durability and reliability mean that with proper maintenance, they can serve an organization for many years, providing an excellent return on investment.

Choosing the Right Bridge Crane for Your Operations

Assessing Your Lifting Needs

Before selecting a bridge crane, it’s crucial to assess your specific lifting requirements. Factors to consider include the weight and dimensions of the loads, the frequency of lifts, and the layout of your workspace. Understanding these parameters helps in choosing the right type and specifications of the crane to ensure it meets operational demands efficiently.

Evaluating Crane Specifications

When choosing a bridge crane, carefully evaluate the specifications such as load capacity, span length, lifting height, and speed. Each specification plays a critical role in determining the suitability of the crane for your specific applications. For example, a double girder crane might be necessary for heavy-duty applications, while a single girder crane could suffice for lighter tasks.

Common Mistakes to Avoid When Selecting a Bridge Crane

It’s essential to avoid common pitfalls when selecting a bridge crane:

- Underestimating Load Requirements: Always account for potential load fluctuations to prevent overloading.

- Ignoring Space Constraints: Ensure the crane fits within available space and adheres to height restrictions.

- Neglecting Safety Features: Opting for cost over safety can lead to long-term operational issues and compliance failures.

Installation and Maintenance of Bridge Cranes

Best Practices for Installation

Proper installation of bridge cranes is vital for ensuring safe and efficient operation. Best practices include:

- Professional Installation: Always have qualified personnel complete the installation to ensure adherence to safety standards.

- Accurate Alignment: Ensure that the crane is installed straight, as misalignment can lead to operational issues and increased wear.

- Adherence to Manufacturer Guidelines: Follow specific manufacturer instructions for installation to maintain warranty validity.

Routine Maintenance Tips for Longevity

To extend the lifespan of your bridge crane, establish a robust maintenance schedule that includes:

- Regular Inspections: Check for wear and tear, including cables, wheels, and controls.

- Lubrication of Moving Parts: Ensure smooth operation by lubricating all moving components regularly.

- Keeping Records: Document maintenance activities to track performance and address potential issues proactively.

Common Issues and Troubleshooting Techniques

Bridge cranes can encounter various issues that need addressing promptly. Common problems include:

- Inconsistent Lifting: This may arise from hoist problems; troubleshooting requires checking the hoist mechanism and control systems.

- Excessive Wear: Regularly inspect all components for wear and replace parts as necessary to prevent further damage.

- Electrical Failures: Ensure that all electrical systems are functioning correctly and replace any defective components.

Future Trends in Bridge Crane Technology

Innovative Features to Look For in 2025

As technology evolves, bridge cranes are becoming more sophisticated. Features to watch for in 2025 include:

- Smart Technology: Integration of IoT devices for remote monitoring and predictive maintenance.

- Enhanced Safety Features: Advanced load sensing and obstacle detection systems that prevent accidents.

- Energy-Efficient Designs: Innovations that reduce energy consumption and improve operational efficiency.

Impact of Automation on Bridge Cranes

Automation is set to drastically change the landscape of bridge cranes. The advent of automated guided vehicles (AGVs) and robotic controls will facilitate seamless operation, allowing for precision lifting and movement. This will not only enhance productivity but also reduce the risk of human error, which is a significant contributor to workplace accidents.

Regulatory Changes and What They Mean for Businesses

As the industry progresses, regulatory changes will likely impact how businesses operate bridge cranes. Staying informed about OSHA regulations and industry standards is crucial for compliance. Companies must also be proactive in adapting to new regulations, which may involve upgrading equipment or training employees to ensure safe operation.

Leave a Reply