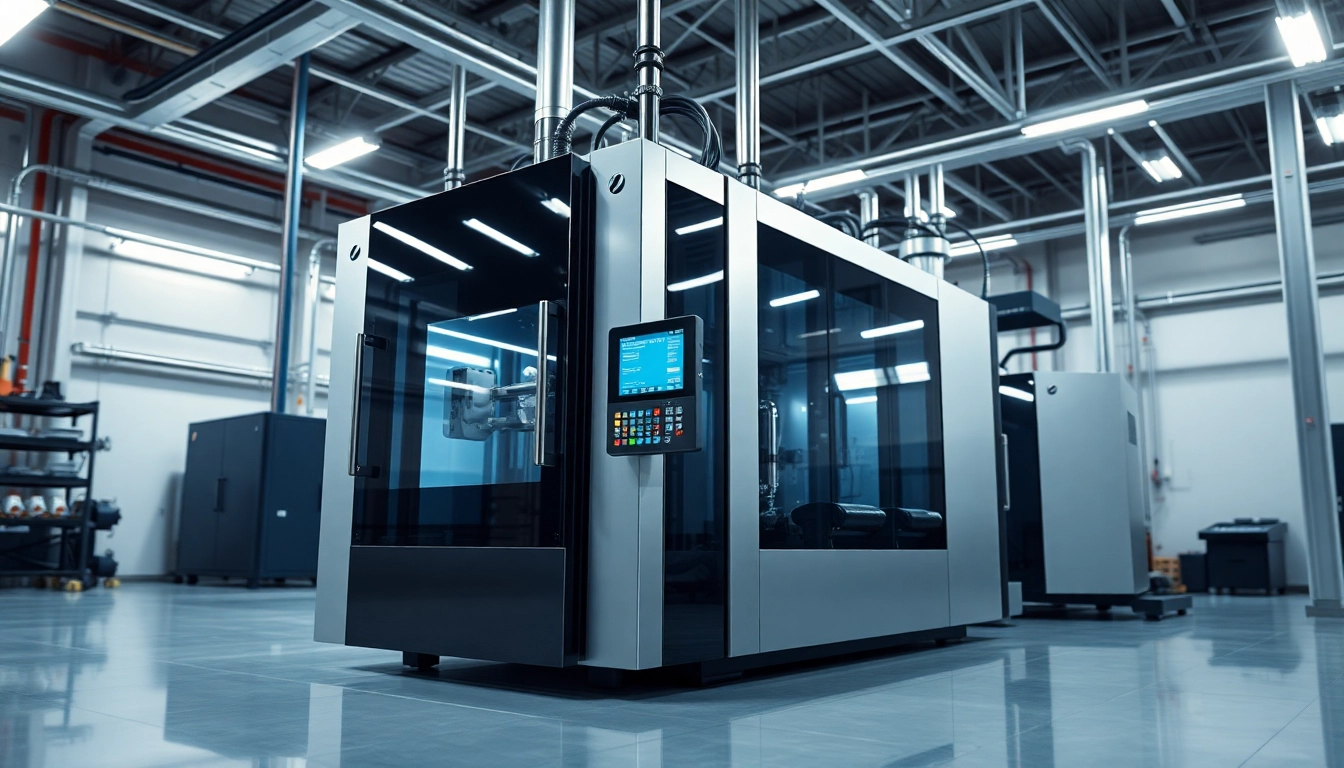

Understanding Mould Temperature Controllers

Mould Temperature Controllers are essential components in various manufacturing processes, particularly in the plastic and metal molding industries. These devices regulate the temperature of the moulds used to shape materials, ensuring that the production process yields high-quality results. Proper temperature control not only impacts product quality but also optimizes production efficiency, minimizes energy consumption, and reduces waste. When exploring options, Mould Temperature Controller solutions can provide comprehensive insights into the technology and functionalities available in the market today.

Definition and Functionality of Mould Temperature Controllers

A Mould Temperature Controller (MTC) is a device that manages the temperature of mould surfaces during the injection molding process. It operates by circulating a heating or cooling medium—most commonly water or oil—through the mould to achieve the desired operational temperature. The MTC can maintain consistent temperature ranges, which is crucial for preventing defects such as warping, incomplete filling, or inadequate surface finish.

Importance of Mould Temperature Control in Production

The significance of effective mould temperature control cannot be overstated in production settings. Proper temperature management leads to:

- Enhanced Product Quality: Maintaining the right temperature ensures uniform material properties and reduces defects.

- Improved Cycle Times: Optimal temperature control can facilitate quicker cooling and heating, thereby decreasing the overall production time.

- Energy Efficiency: Precise control reduces unnecessary heating and cooling, optimizing energy consumption and lowering operational costs.

- Increased Equipment Longevity: With proper temperature management, wear and tear on moulds are minimized, extending their lifespan.

Key Components and Technologies Used

An effective mould temperature controller typically comprises several critical components, including:

- Heating and Cooling Elements: These are responsible for the thermal regulation of the mould, with options ranging from electric heaters to hot oil systems.

- Temperature Sensors: These devices monitor the temperature of the mould and provide feedback to the controller for adjustments.

- Pumps: Pumps circulate the heating or cooling medium throughout the system, ensuring consistent temperature distribution.

- Control Panel: Modern MTCs feature user-friendly interfaces for easy programming and monitoring of temperature settings.

How to Select the Right Mould Temperature Controller

Choosing the right mould temperature controller involves considering several factors that align with your specific production needs and conditions.

Factors to Consider When Choosing a Mould Temperature Controller

Key considerations include:

- Temperature Range: Different processes require different temperature ranges, so ensure that the MTC can accommodate your operational needs.

- Medium Type: Decide whether you need a water-based or oil-based system, as this will affect performance and compatibility with your mould materials.

- Flow Rate: A sufficient flow rate is necessary to ensure uniform temperature across the mould.

- Energy Efficiency: Look for models designed for energy savings without sacrificing performance.

- Scalability: Consider whether the controller can be adapted or scaled for future production expansion.

Comparative Analysis of Leading Brands

The market offers a variety of brands known for their reliable mould temperature controllers. Each brand may focus on specific features:

- Topstar: Known for innovative technology, their controllers emphasize fast heating and low water leakage.

- Regloplas: Offers temperature control solutions with high precision, focusing on various temperature ranges.

- Mold-Masters: Their TempMaster series integrates seamlessly with various injection molding machines.

- Delta T Systems: Provides engineered solutions with a strong emphasis on precision and reliability.

When selecting a brand, consider how their offerings align with your production objectives and demands.

Cost vs. Performance Evaluation

While it may be tempting to opt for the least expensive model, it is crucial to evaluate the cost relative to performance. Higher upfront costs can sometimes be offset by long-term savings in energy efficiency and reduced downtime. Conducting a total cost of ownership analysis helps clarify which Mould Temperature Controllers deliver the best value over time.

Installation and Maintenance Best Practices

Proper installation and maintenance are critical for maximizing the performance and longevity of mould temperature controllers.

Step-by-Step Installation Guide

- Plan the Installation: Assess the site conditions, ensuring that there’s adequate space for the MTC and associated plumbing and electrical connections.

- Connect the Cooling/Heating Medium: Install piping for heating or cooling mediums based on your system’s design.

- Set Up the Electrical Connections: Ensure all electrical wiring complies with safety standards and is securely connected.

- Install Sensors: Position temperature sensors accurately within the mould for precise readings.

- Test the System: Conduct thorough testing to verify that heating and cooling functions work as intended before commencing full production.

Regular Maintenance Tips for Optimal Performance

To maintain the efficiency of mould temperature controllers, regular maintenance is essential:

- Routine Cleaning: Keep the pumps and filters clean to ensure optimal flow rates and prevent blockages.

- Calibration Checks: Regularly calibrate temperature sensors for accurate readings.

- Inspect for Leaks: Frequently check for leaks in piping and seals to avoid fluid loss.

- Monitor Performance: Keep track of performance metrics to identify any issues early.

Troubleshooting Common Issues

Even the best systems can encounter issues. Common problems include:

- Temperature Fluctuations: May indicate sensor issues or inconsistent flow rates.

- Insufficient Heating or Cooling: Often caused by blockages in piping or pump failure.

- System Leaks: Should be addressed immediately to prevent operational disruptions.

Innovative Features of Modern Mould Temperature Controllers

As technology advances, modern mould temperature controllers are incorporating features that enhance functionality and efficiency.

Smart Technology Integration and IoT Applications

Many contemporary MTCs are equipped with smart technology that allows for remote monitoring and control. Integration with IoT applications enables manufacturers to collect data in real-time, facilitating proactive decision-making regarding maintenance and operational adjustments.

Energy Efficiency Enhancements for Sustainable Practices

With increasing focus on sustainability, manufacturers are prioritizing energy-efficient designs. New models utilize advanced insulation materials and optimized flow paths to minimize energy loss, thereby lowering operational costs and environmental impact.

Latest Trends in Automation and Control Systems

Automation trends are shaping the future of mould temperature control. Systems are now equipped with AI algorithms that can predict temperature changes based on historical data, allowing for automatic adjustments and further ensuring consistent processing conditions.

Future Trends in Mould Temperature Control

As we look towards 2025 and beyond, several trends are expected to shape the mould temperature control landscape.

Predictions for Mould Temperature Technologies by 2025

Expect advancements in materials technology, leading to controllers that can operate at even higher temperatures and with improved energy efficiency. Additionally, the integration of nanotechnology in heating elements may enhance performance and reliability.

Impact of Industry 4.0 on Temperature Control Systems

Industry 4.0 is set to revolutionize mould temperature control through greater use of data analytics and machine learning. These technologies will enable more precise control and optimization of the entire manufacturing process, contributing to higher quality products and lower waste.

Case Studies: Successful Implementations in Various Industries

Numerous industries, from automotive to consumer goods, have successfully implemented advanced mould temperature controllers to streamline operations and improve product quality. For instance, a leading automotive manufacturer switched to smart MTCs, resulting in a 20% reduction in cycle times and a significant decrease in scrap rates.

Leave a Reply